Archive for the ‘3D Stuffs’ Category

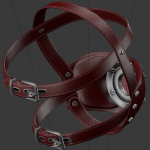

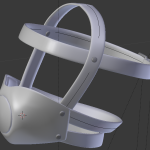

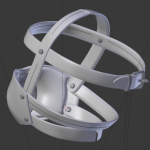

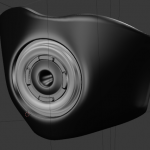

Inworld test successful!

For some reason i had to juggle between two clients to get the mask to upload the way i wanted it. Also my lighting is strange, but that might just the the place I’m at.

Almost there really, now it’s time to start scripting.

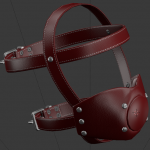

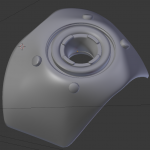

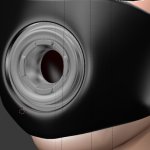

First texture draft on the muzzle gag

Figured it was about time to post another peek at the texture work. This is pretty much the final aspect, now all I need to do is the tedious process of rendering all the colors and assembling them.

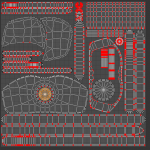

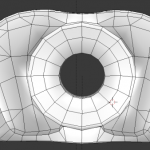

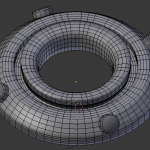

Main UVs done!

The UVs for the harness and its main plug are done, I’ve done some compromising with the inner surfaces getting less texture area than the outer faces, I think I’m getting the hang of it with this kind of optimization… slowly. The “classic” mistakes were made which means I had to redo some areas more than once, and ended up splitting the longest strap in two (which I did for the blindfold, but forgot about!)

I will take care of the accessories once I’ve worked out future texture issues.

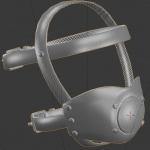

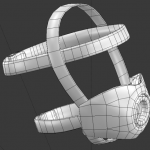

LPM In the work

I still have to finish the LPM forehead strap (lots of tweaking but I did this like a newbie -_- )

More strap work, alternate solution.

I settled on a different strap layout in the end, the double chin strap was nice, but it was too bulky and clipped the ear with no real way around it. So I added a chin strap and removed one of the neck straps. Here is a before/after picture.

Straps and more straps.

Fairly slow progress there, I’ve initially used “thin” straps, the same that I used on the braced collar, but then I settled against them and used the ones from the blindfold, which are my standard width straps (I think?), I’ve also changed the edge bevel style twice now… I can still make my mind on that but still, at some point I’m gonna have to pick.

The two bottom straps are in a really tight spot but I cannot see myself using only one. It wouldn’t make sense structurally.

I haven’t decided for or against having an under-jaw strap, I’m just worried that the buckle for it, even a small one, might cause problems when worn with the braced collar, and making it lockable is simply not an option… Maybe a fixed strap then?

Riveting, padding and a bunch of adjustments.

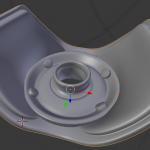

With yesterday’s tests, I figured the most “logical” solution was to put the rivets on a conical surface rather than a flat one. Again this is “design” stuff and serve no purpose to the creation of the object itself, but is useful to ensure that it will look ‘right”… And that’s important.

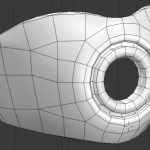

There is now a groove in the fitting to accommodate the outer cap lip (there is also a slight taper but that’s not really visible) and make the leather a little thinner around the hole. I quickly built up the padding on the back side and added the opposite heads of the rivets.

Not in the pictures, I considerably extended the sides because it is supposed to go almost at ear level for the straps to work, I also removed a section of the padding in this area. Unless I change my mind, that’s where the straps will be attached (on the underside basically)

I’m gonna leave this part alone for a little while now and focus on the straps.

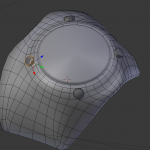

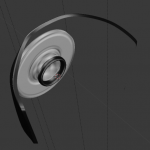

Second draft, getting somewhere.

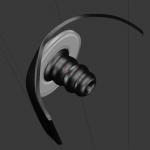

After yesterday’s pathetic attempt I decided to start with the metallic elements first to get a sense of how much headroom I will need to get everything in place. This led to a much better result. While making those internal plugs in all their details isn’t really that important, they help going through the design process. I’m pretty happy with the layout, the external rubber cap is nice and flush with the rest.

I like those “industrial looking” surface notches, normally you use these with a sort of socket wrench to tighten some fittings. As with the rest of my leather objects, the back of the leather panel will receive some generous padding to get rid of most of the gaps.

First draft on my panel gag

And it’s … kind of bad. I should probably start with the metal gag part and then build the panel around it, this doesn’t really do it for me.